Heron

Heron Mi 4, 8, 12 or 16 Station Irrigation Controllers

- SKU:

- CON0200A

- Availability:

- In Stock

- Shipping:

- Calculated at Checkout

Description

Heron Mi 4, 8, 12 or 16 Station Multi Wire Irrigation Controllers

Mi- Program Specification

- Up to 60 independent programs.

- Run up to 6 valves in parallel as standard

- Possibility to run up to 12 valves in parallel with additional output cards.

- Up to 64 automatic starts.

- Daily, weekly and variable period automatic starts.

- Automatic starts can be set to run on odd or even days.

- Valves can be individually named e.g. Lawn1, Bed1.

- Valves can be specified to run on a time or volume basis.

- Valves can be allocated to one of five water meters.

- An optimal flow can be entered for every valve.

- A minimum, maximum and pipe break flow rate can be specified for each water meter.

- Valve times can be set from a minimum of 1 second to 10 hours.

- Valves can be allocated to an irrigation group.

- Rainfall can be monitored over 1 to 4 days, irrigation programs can be reduced by 25%, 50%, 75% or 100%.

- Manually percentage adjust (0% to 250%) .

- Separate manual percentage adjust for programs and valve groups.

- Continual cycling of irrigation programs between specified time of day. Delay between cycles can be set from 1 minute to 9 hours.

- Manually start an individual program or valve.

- Manually start multiple programs.

- User can select which program to stop or manually advance if multiple programs are running.

- Pump pressurisation time can be set in minutes and seconds.

- Programs can be configured to start, stop, freeze or manually advance on a remote input.

- Up to 10 remote inputs can be connected.

- Programs can be allocated up to 5 pump starts or master valves.

- Valves can be defined as ‘special outputs’ to control external devices e.g. fill a pond, switch lighting.

- Valves can be defined for back flush use.

- Irrigation programs can be inhibited by wind speed or wind direction.

- Programs can be integrated with light, rain, humidity, temperature sensors.

- Irrigation can be controlled from a calculated evapotranspiration (ET) value.

- The ET value can be calculated using a variety of sensors depending upon the required accuracy.

- Programs can be attached to a dosing recipe.

Mi-144 Hardware Specification

- Compatible with any 24V AC solenoid valve.

- Option to operate DC valves.

- Output current 1.2amps (resistive) with electronic overload cut-out.

- Output current is measured which can be displayed for diagnostic purposes.

- Two pump starts.

- Three digital inputs.

- One socket to connect additional cards

- Two sockets for connecting additional output boxes.

- One data conector to connect to a PC or GSM mobile phone module.

- Designed to operate in an industrial environment. High electrical noise immunity, can withstand a 2.5KV spike.

- Battery backed up real tme clock. Real time clock immune to high electrical noise.

- All outputs protected against electrical surges exceeding ANSI C62 surge suppression standards.

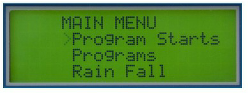

Easy to use

Heron's controllers are menu driven, making them intuitive and easy to use.

To simplify the creation of irrigation programs, valves can be individually named. Irrigation programs can be customised, allowing the user to change the valve order, add and delete valves.

Integrate with sensors and dosing systems

- Mi controllers can be integrated with sensors and dosing systems.

- Irrigation can be controlled by light, rain, temperature, humidity, wind speed, wind direction or flow meters.

- For example, your Mi controller can be set up to :

- Operate a misting irrigation program initiated by light and humidity.

- The misting irrigation program can be set to take priority over outside irrigation programs.

- The outside irrigation can be configured to reduce based on rain fall.